Now with additional food safety features! Fuiyoh!

I’ve been thinking about it for a long time, and I decided to revisit my design for the King of Flavor MSG Shaker. As I discussed in the previous post, 3D printed stuff is not technically food safe. For the purpose of storing solid materials like grains of MSG, it was fine, but it nagged at the back of my mind.

There are various food safety issues to consider when 3D printing, especially in the USA where people take food safety almost religiously:

- Lead in printer nozzles

Brass 3D printer nozzles have about 2% lead by weight. This lead is in metal form, and isn’t going to be incorporated into the part or breathed or eaten, but some kinds of 3D printing filament that contain hard things like rocks are abrasive and can cause that nozzle to wear off into the plastic. Using a smooth filament, this is even less of an issue. For the purpose of scale, though, the amount of lead that could possibly be near food in a design like this (if you were to magically vaporize a big chunk of the print nozzle without the printer failing) is less than if you used a lead pencil on on a sheet of paper to write the dot in the letter i. - Microplastics

The plastic on the surface of the 3D printed part can be worn off by food stored next to it, and 3D printing can also leave behind loose bits of plastic. The health effects of eating microplastics aren’t fully known, but we know enough that it’s generally not good. - Rough surfaces

3D printed parts have lots of little nooks and crannies in between the layers that are very hard to wash. These are good places for bacteria to grow. This is pretty much not an issue for storing dry solids, but not great for things you might want to clean with water. For a lot of food applications, I would print a part in ABS and then smooth the surface with an acetone bath, but it’s really hard to do that to the inside of something. For one thing, I can’t reliably inspect the inside to make sure the acetone didn’t eat through the shell into the hollow interior of the part, which could trap a lingering odor of paint thinner in the part. - Toxic plastics

If you use a 3D printing filament that is toxic, of course you will get toxic plastic parts, haiyaa.

None of these things concern me about using my original design in the way that I printed it, but I decided to improve the food safety beyond any doubt anyway. It wasn’t that hard, honestly, and I definitely overthought it a lot before I landed on the obvious solution: just store the MSG in a commercial food safe container and print a shell around it.

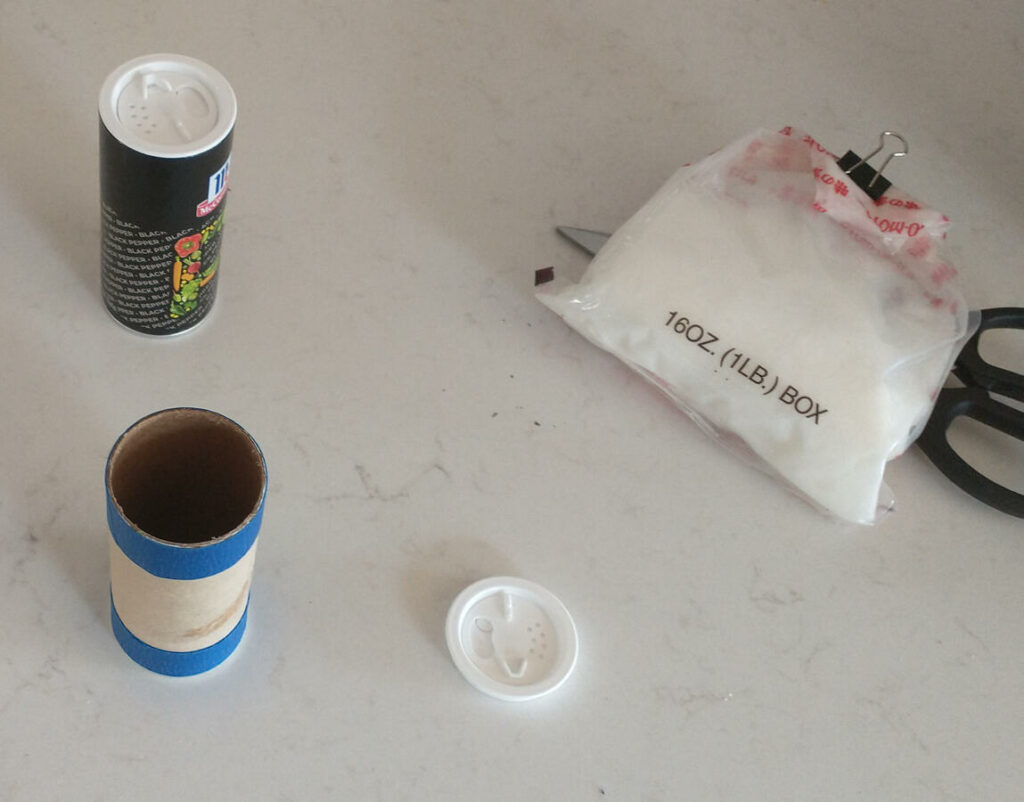

I picked these super cheap salt and pepper shakers from the grocery store for a few reasons:

- They’re everywhere, and they’re cheap.

- They hold a lot of volume, as much as any plastic containers I could reliably find online.

- They’re refillable.

- Other than the plastic lid, they’re made of materials that are biodegradable or recyclable: wax-coated cardboard and aluminum.

- They’re basically cylinders, so the design is a piece of cake.

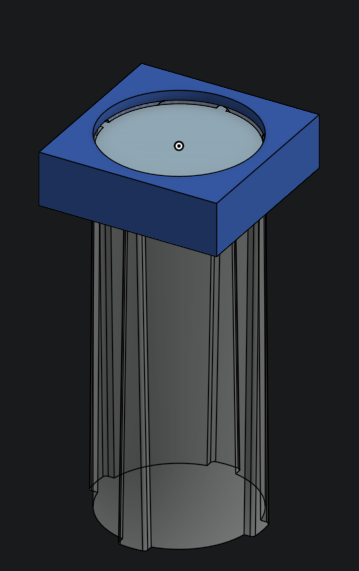

I googled around until I found a design for a 3D-printable twist-locking plug on GrabCAD. I gave it a test and decided I wanted to design my own version of it so that I could have it in my toolbox for future projects.

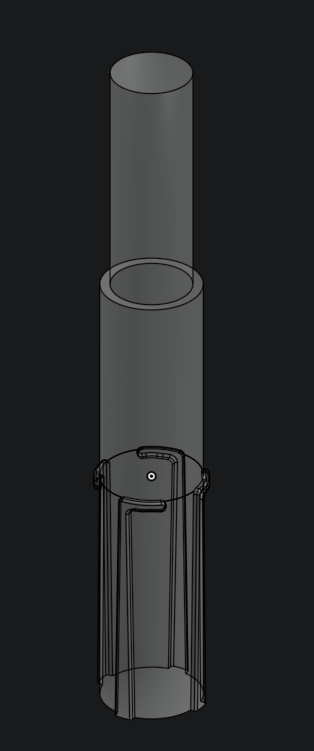

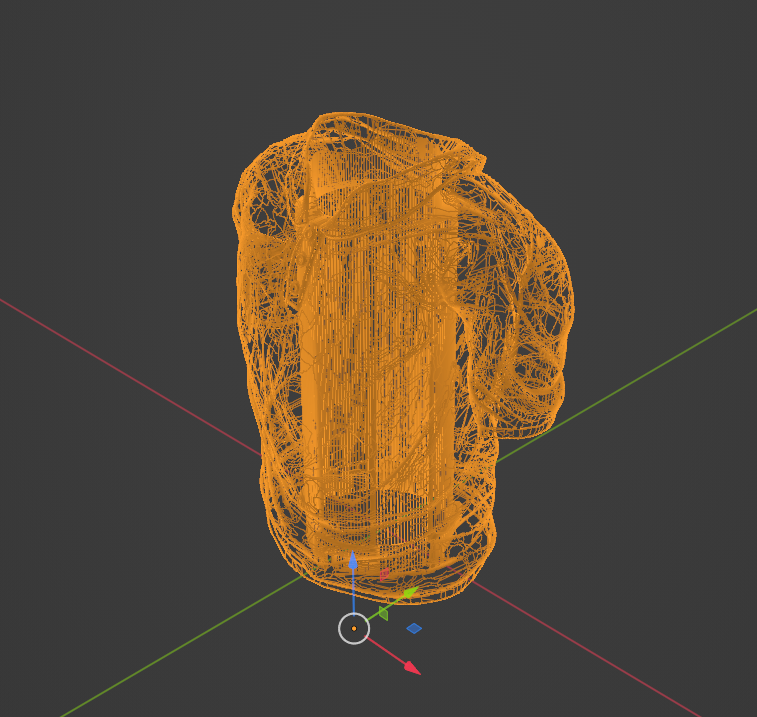

I modeled the cylinder and the clearance over the cylinder and combined that shape with the shape of the opening that the twist-locking plug slots into in Onshape. I imported that model into my Blender project and reapplied the boolean operation. I did a few test prints of the interfaces to get the fit nice and tight.

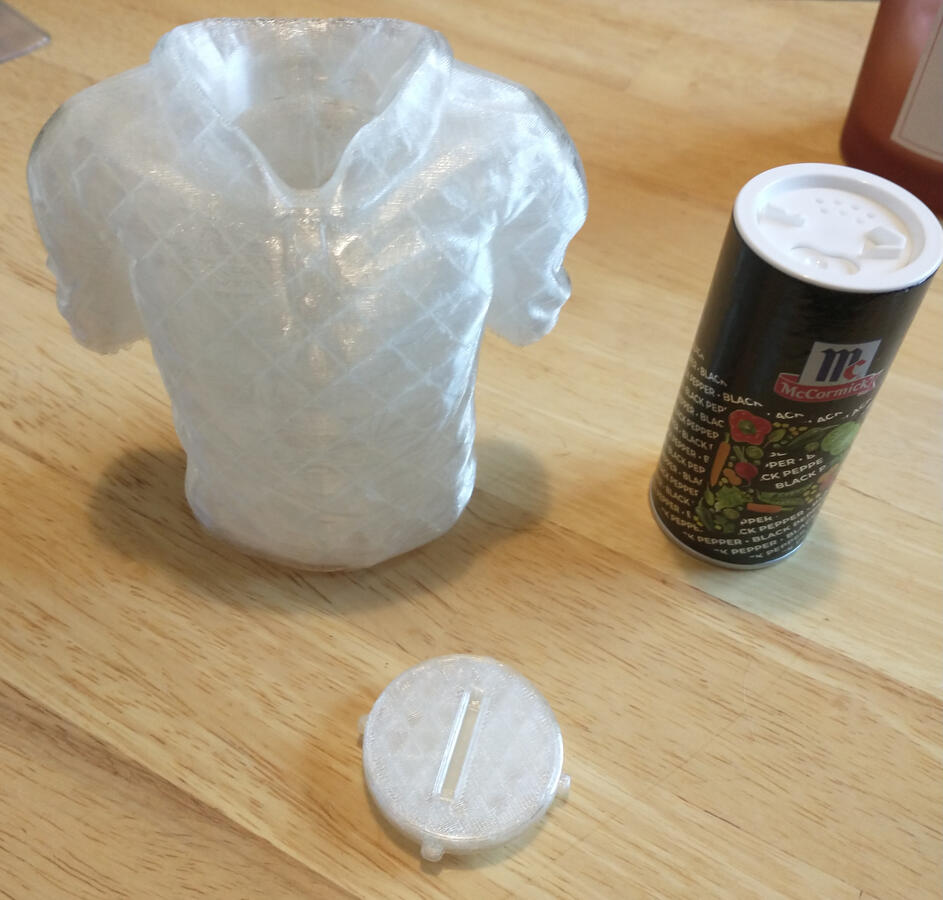

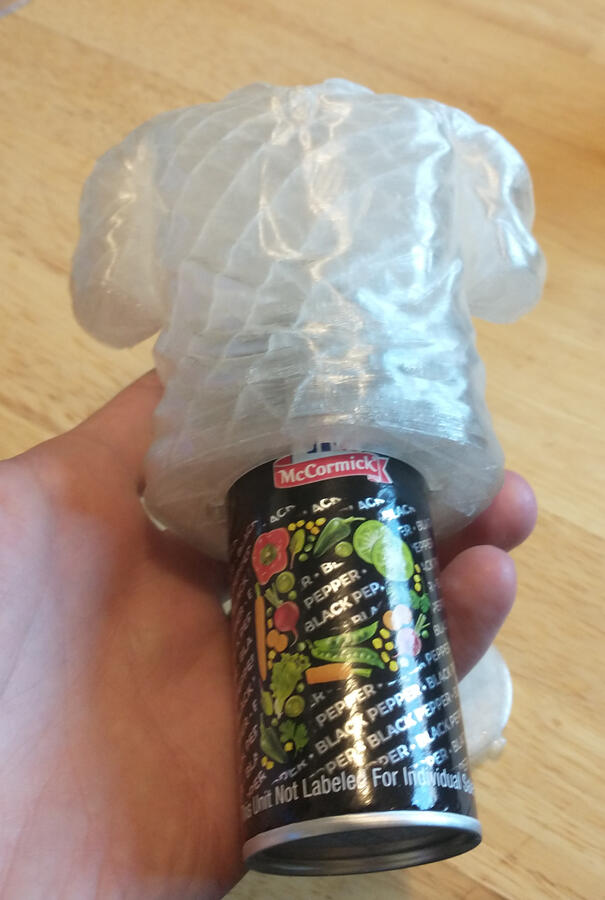

I ran a test print in a transparent PLA so you can kind of see the big black cylinder shoved up inside.

I put a piece of window insulation foam on the inside of the plug so that it presses the shaker firmly up, and I wrapped the cylinder in a little bit of masking tape so that it has a nice tight fit and doesn’t move at all when you shake it. Finally, I ran off a few prints in orange, filled the shaker with MSG, and started using it.

If you would also like a King of Flavor MSG Shaker, the STL files are available on Thangs here.

If you would like to use my locking lid model in Onshape, you can find it here. You can also find the salt shaker cavity shape here, just in case you want to use the same approach in your own flavor-dispensing project.

I wonder if I should make a plaid shirt holder for a bottle of olive oil….